Lijia Chain Co., Ltd is famous China Ring Skidder Chain Manufacturers and Ring Skidder Chains factory. Company has introduced advanced technology and equipment, including 7 sets of high-strength chain special automatic braiding and welding machines; 3 sets of special chain intermediate frequency quenching equipment; 7 correction machines; Complete testing equipment such as tensile testing machine and hardness machine. So we can custom ring skidder chains worldwide. Just tell what you need, we would offer perfect lifting chain products & solution. The Products Are Sold At Home And Abroad And Are Widely Welcomed By Customers. At Present, The Company Has Formed An Annual Production Capacity Of 3,000 Tons Of High-Strength Chains.

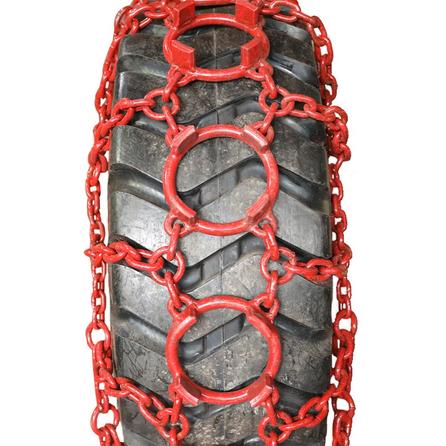

Ring skidder chains are a specialized type of skidder chain that offer unique advantages in the logging industry. These chains, featuring a ring-shaped design, have been developed to enhance performance and durability in demanding logging operations. Let's explore how ring skidder chains contribute to improved efficiency and longevity in logging operations.

The design of ring skidder chains is specifically engineered to provide exceptional performance in challenging terrains encountered in logging operations. Unlike traditional skidder chains, which consist of straight links, ring skidder chains form a continuous loop, resembling a ring. This innovative design offers several key benefits.

Firstly, the continuous loop design of ring skidder chains ensures consistent traction throughout the entire chain length. The absence of inpidual links eliminates weak points and potential areas of slippage, resulting in a more secure grip on the ground or logs. This enhanced traction enables skidders to operate more effectively on steep slopes, uneven surfaces, and other difficult terrains commonly found in logging operations.

Moreover, the continuous loop design of ring skidder chains contributes to improved durability. Traditional skidder chains often experience wear and tear at the connection points between inpidual links, which can lead to chain failure and the need for frequent replacements. In contrast, ring skidder chains eliminate these weak points, reducing the risk of breakage and extending the lifespan of the chains. This increased durability translates into cost savings for logging companies, as they can minimize the frequency of chain replacements and associated downtime.

Another advantage of ring skidder chains is their ability to distribute load more evenly. The ring design allows for better weight distribution across the entire chain, reducing stress on inpidual links. This even load distribution helps to prevent premature wear and breakage, enhancing the overall strength and longevity of the chain. As a result, logging companies can rely on ring skidder chains to withstand heavy loads and prolonged use, ensuring continued productivity and reducing operational disruptions.

Furthermore, ring skidder chains offer ease of installation and maintenance. Their continuous loop design simplifies the installation process, as there is no need to connect inpidual links. This saves valuable time and effort for the operators, enabling them to focus on other essential tasks. Additionally, the reduced susceptibility to wear and breakage in ring skidder chains means that maintenance requirements are minimized. Regular inspections and routine maintenance can be carried out efficiently, ensuring optimal performance and safety without significant interruptions to operations.

In conclusion, ring skidder chains represent a significant advancement in the logging industry, providing improved performance and durability. The continuous loop design ensures consistent traction, enhanced load distribution, and increased longevity, making them a reliable choice for logging companies. By investing in ring skidder chains, logging companies can optimize their operations, reduce maintenance costs, and improve overall productivity. These chains are a testament to the ongoing innovation in the logging industry, where specialized equipment and tools continue to drive efficiency and safety in demanding logging operations.

Ring skidder chains are specialized traction devices used in forestry applications to enhance the performance and safety of skidders. Skidders are heavy-duty machines used for hauling logs and timber in challenging terrains. Ring skidder chains are designed with interconnected rings that provide exceptional grip and traction, allowing skidders to maneuver through rough and slippery surfaces with ease. We will explore the advantages of using ring skidder chains in forestry applications and how they compare to other skidder chain designs.

Enhanced Traction and Stability:

Ring skidder chains offer superior traction and stability, which are crucial in forestry applications. The interconnected ring design provides multiple contact points with the ground surface, allowing for maximum grip. This design ensures that the chains evenly distribute the load and provide consistent traction, even in challenging terrains such as steep slopes, muddy areas, or icy surfaces. The enhanced traction and stability of ring skidder chains enable skidders to maintain control, reduce slippage, and improve overall operational efficiency.

Reduced Chain Damage:

Compared to other skidder chain designs, ring skidder chains have the advantage of reduced chain damage. Traditional skidder chains with inpidual links can be more susceptible to damage and breakage when subjected to the stress and strain of forestry operations. The interconnected rings of ring skidder chains provide a more robust and resilient structure. The continuous ring design minimizes weak points and vulnerable areas, resulting in reduced chain breakage and the need for frequent replacements. This durability translates into cost savings and increased uptime for forestry operators.

Enhanced Flexibility and Maneuverability:

Ring skidder chains offer enhanced flexibility and maneuverability, making them well-suited for forestry applications. The interconnected rings allow for greater articulation and flexibility, enabling the chains to conform to uneven terrain and obstacles. This flexibility enhances the skidder's maneuverability, allowing it to navigate through tight spaces and challenging terrains with ease. The improved maneuverability of ring skidder chains increases the efficiency of forestry operations and enables skidders to access remote or difficult-to-reach areas.

Minimized Ground Disturbance:

Forestry operations often take place in environmentally sensitive areas, where minimizing ground disturbance is crucial. Ring skidder chains help reduce ground disturbance compared to other skidder chain designs. The continuous ring structure distributes the weight more evenly across the ground surface, reducing soil compaction and minimizing damage to the underlying soil and vegetation. This benefit is particularly important for preserving sensitive ecosystems and minimizing environmental impact in forestry operations.

Operator Safety:

Safety is paramount in forestry applications, and ring skidder chains contribute to improved operator safety. The enhanced traction and stability provided by ring skidder chains minimize the risk of skidders losing control, sliding, or tipping over in challenging terrains. This reduces the likelihood of accidents, injuries, and property damage. The improved safety provided by ring skidder chains creates a safer working environment for operators and enhances overall productivity in forestry operations.

Ring skidder chains offer several advantages over other skidder chain designs in forestry applications. The enhanced traction, stability, and maneuverability provided by ring skidder chains improve operational efficiency and productivity. The reduced chain damage and minimized ground disturbance contribute to cost savings and environmental sustainability. Additionally, the improved operator safety ensures a safer working environment. By utilizing ring skidder chains, forestry operators can enhance their capabilities, optimize their operations, and achieve greater success in the logging industry.

In the mining industry, the operating environment of the mine is complex and changeable. Can the lifting chain adapt to the lifting needs at different...

READ MOREIn the mining industry, mining equipment often requires customized chain solutions. Can the ease of processing of Mild Steel Link Chain help meet thes...

READ MOREIn the construction industry, engineering vehicles often work on muddy construction sites. Is Tire Chain favored for its easy installation and removal...

READ MOREIn the field of shipbuilding, has Mild Steel Link Chain become an ideal choice for building ship anchor chains, guardrails and other components due to...

READ MOREThere are many type of chain products, for almost all lifting project & solution.

Contact Us