Lijia Chain Co., Ltd is famous China G100 chain fittings Manufacturers and G100 chain fittings factory. Company has introduced advanced technology and equipment, including 7 sets of high-strength chain special automatic braiding and welding machines; 3 sets of special chain intermediate frequency quenching equipment; 7 correction machines; Complete testing equipment such as tensile testing machine and hardness machine. So we can custom G100 chain fittings worldwide. Just tell what you need, we would offer perfect lifting chain products & solution. The Products Are Sold At Home And Abroad And Are Widely Welcomed By Customers. At Present, The Company Has Formed An Annual Production Capacity Of 3,000 Tons Of High-Strength Chains.

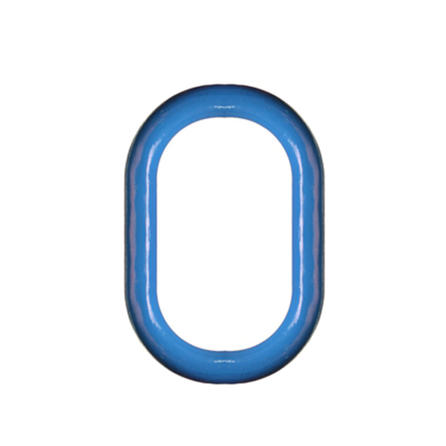

G100 chain fittings are essential components in heavy-duty lifting and rigging operations, offering numerous advantages and applications across various industries. As a manufacturer, supplier, or user of G100 chain fittings, understanding their key benefits and suitable applications is crucial. We will explore the advantages and applications of G100 chain fittings, providing valuable insights into their importance in heavy-duty lifting and rigging operations.

Advantages of G100 Chain Fittings:

Exceptional Strength and Durability:

G100 chain fittings are known for their exceptional strength and durability. They are manufactured from high-quality alloy steel, which allows them to withstand heavy loads and harsh working conditions. The superior strength of G100 chain fittings ensures their reliability and longevity, providing a safe and efficient lifting and rigging solution for heavy-duty applications.

Higher Working Load Limits (WLL):

One of the key advantages of G100 chain fittings is their higher working load limits (WLL) compared to lower-grade fittings. G100 chain fittings have a significantly higher load capacity, allowing them to handle heavier loads with greater safety margins. This increased load capacity enhances the efficiency and safety of heavy-duty lifting and rigging operations.

Enhanced Safety Features:

G100 chain fittings are designed with enhanced safety features to ensure secure lifting and rigging operations. These fittings often incorporate safety mechanisms such as safety latches or hooks with self-closing systems, reducing the risk of accidental detachment. The inclusion of these safety features enhances overall workplace safety and minimizes the potential for accidents or equipment failure during heavy-duty operations.

Excellent Corrosion Resistance:

G100 chain fittings are often treated with protective coatings or finishes to enhance their corrosion resistance. This is particularly important in industries where the fittings may be exposed to harsh environments, moisture, or corrosive substances. The corrosion resistance of G100 chain fittings ensures their longevity, reduces the need for frequent maintenance, and guarantees their performance in challenging conditions.

Applications of G100 Chain Fittings:

Construction and Infrastructure Projects:

G100 chain fittings find extensive applications in construction and infrastructure projects. These fittings are utilized for heavy lifting and rigging tasks, such as lifting steel beams, precast concrete elements, or large construction components. The exceptional strength, durability, and higher load capacity of G100 chain fittings make them indispensable in these demanding construction applications.

Offshore and Marine Industry:

In the offshore and marine industry, G100 chain fittings are crucial for lifting and rigging operations on oil rigs, ships, and offshore platforms. They are used for tasks such as hoisting heavy equipment, securing loads, or handling underwater installations. The high strength, durability, and corrosion resistance of G100 chain fittings make them well-suited for the harsh and corrosive environments encountered in the offshore and marine industries.

Manufacturing and Heavy Industrial Settings:

G100 chain fittings are commonly employed in manufacturing and heavy industrial settings where heavy machinery, equipment, or components need to be lifted, moved, or secured. They are used in assembly lines, material handling processes, or maintenance operations. The high load capacity and durability of G100 chain fittings make them an ideal choice for these demanding industrial applications.

Mining and Extraction Operations:

In the mining and extraction industry, G100 chain fittings play a critical role in heavy-duty lifting and rigging tasks. They are utilized for lifting and moving heavy equipment, securing loads during mining operations, or handling ore and extracted materials. The exceptional strength and reliability of G100 chain fittings ensure safe and efficient operations in the challenging conditions of the mining industry.

In summary, G100 chain fittings offer numerous advantages and applications in heavy-duty lifting and rigging operations. Their exceptional strength, higher working load limits, enhanced safety features, and corrosion resistance make them a reliable choice for industries such as construction, offshore and marine, manufacturing, and mining. Incorporating G100 chain fittings into heavy-duty lifting and rigging operations ensures the safety, efficiency, and success of these demanding industrial applications.

In the mining industry, the operating environment of the mine is complex and changeable. Can the lifting chain adapt to the lifting needs at different...

READ MOREIn the mining industry, mining equipment often requires customized chain solutions. Can the ease of processing of Mild Steel Link Chain help meet thes...

READ MOREIn the construction industry, engineering vehicles often work on muddy construction sites. Is Tire Chain favored for its easy installation and removal...

READ MOREIn the field of shipbuilding, has Mild Steel Link Chain become an ideal choice for building ship anchor chains, guardrails and other components due to...

READ MOREThere are many type of chain products, for almost all lifting project & solution.

Contact Us